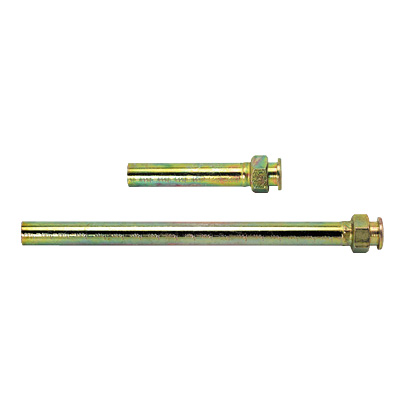

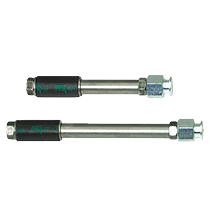

Pressure element 13 mm

Order no.: V13DF, V13DLF

-

-

Item description

TWO-PART COMPOSITE PACKERS as an alternative for injection packers

Both parts can be combined differently, thus there is a variety of possible applications!

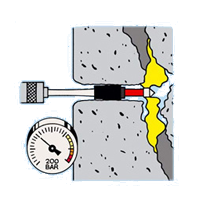

Composite packers are suitable for low pressure and high pressure, due to a low opening pressure of circa 1-2 bar. The advantage is both the saving of time as described below, and that the pressure elements can be used repeatedly.

Handling and pressing is the same as with the service-proven drill-hole packers.

The decisive advantage: the pressure element (front part) can be removed after injection without any loss of pressure while, the drill hole can be closed straight away.

This means: less time and labour must be expended.

The pressure element, if cleaned well, may be used again more than 5 times.

Lowering the packer element is simple because of pressure elements being available in varying lengths.

The composite packer can be retightened (as opposed to the impact packing element), thus there is no interruption of the injection process.

Another advantage is the fact that the composite packer can be subjected to much higher pressure than a packer with a pretermined breaking point.

Request info Inquiry basket

Note

n/a

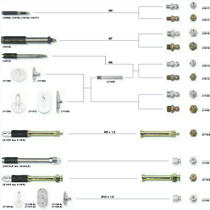

Item details

with flat head, thread M6

steel galvanized

fitting on packer element V13P

Order no.

dia. in mm length in mm Price EUR

(excl. Vat)(V13DF)

13 75 3,96 (V13DLF)

13 175 5,95

-

POLYPLAN

Download catalogue

Download -

PPW-Polyplan-Werkzeuge GmbH

Riekbornweg 20

D-22457 Hamburg

Phone: +49405597260

Fax: +494055972665

E-mail: ppw@polyplan.com -

| back | top |

AEO - Authorised Economic Operator

© PPW-POLYPLAN-WERKZEUGE GmbH

Phone: +49405597260 | Fax: +494055972665 | E-mail: ppw@polyplan.com

Subject to alterations.

Accessories

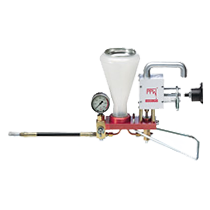

Accessories pumps

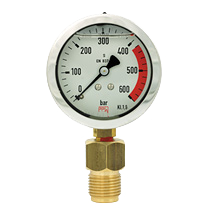

pumps Spare-Pressure gauges

Spare-Pressure gauges Adhesion packer

Adhesion packer Composite packer

Composite packer drill hole packer cone-head

drill hole packer cone-head drill hole packer flat-head

drill hole packer flat-head drill hole packer viscous media

drill hole packer viscous media Hose connections

Hose connections injection packer

injection packer Plastic-Packer

Plastic-Packer Accessories for injection packers

Accessories for injection packers Cocks + couplings

Cocks + couplings nipples

nipples Reducing connections

Reducing connections Cracks?

Cracks? Packer range

Packer range Product film

Product film