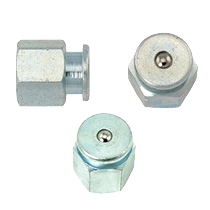

Plastic-injection-packer 10 mm

Order no.: K2010L, K2012

-

-

Item description

Plastic injection packer (European Patent)

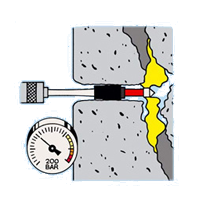

Plastic packer will often be used as low priced alternative for Injection Packers. Normal drive-in packer with lamellas have the disadvantage that the drill hole has to be very accurate to the Diameter, or the packer won`t Keep in the hole. Because of its remarkable combination of integrated nipple-head and two rubber parts it is possible to inject synthetic resin up to 200 bar pressure through the plastic injection packer.

The red rubber at the tip of the packer functions are a non-backflow valve. The injection medium flows out beneath the red rubber during injection but cannot flow back into the packer because of the counter pressure.

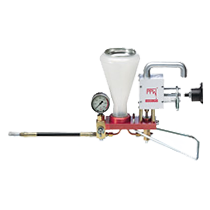

After setting the plastic injection packer into the drill hole the leading plate of the setting-clamp tool can easily be positioned over the nipple-head of the packer. By working the handle of the setting-clamp tool, the black rubber will be drawn and clamped into the drill hole. Through the integrated nipple-head injection can be made with high pressure. Because of the packer material there is no risk of corrosion in opposition to injection packers made of steel.

Request info Inquiry basket

Note

n/a

Item details

fitting on the setting-clamp tool (K2002)

Order no.

dia. in mm length in mm Price EUR

(excl. Vat)(K2010L)

10 120 0,97 (K2012)

12 120 1,09

-

POLYPLAN

Download catalogue

Download -

PPW-Polyplan-Werkzeuge GmbH

Riekbornweg 20

D-22457 Hamburg

Phone: +49405597260

Fax: +494055972665

E-mail: ppw@polyplan.com -

| back | top |

AEO - Authorised Economic Operator

© PPW-POLYPLAN-WERKZEUGE GmbH

Phone: +49405597260 | Fax: +494055972665 | E-mail: ppw@polyplan.com

Subject to alterations.

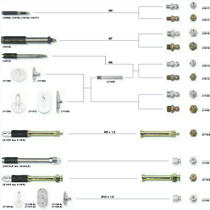

Accessories

Accessories pumps

pumps Spare Pressure gauges

Spare Pressure gauges Adhesion packer

Adhesion packer Composite packer

Composite packer drill hole packer cone-head

drill hole packer cone-head drill hole packer flat-head

drill hole packer flat-head drill hole packer viscous media

drill hole packer viscous media Hose connections

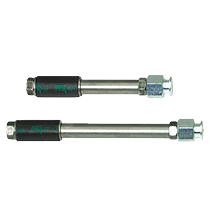

Hose connections injection packer

injection packer Plastic-Packer

Plastic-Packer Accessories for injection packers

Accessories for injection packers Cocks + couplings

Cocks + couplings nipples

nipples Reducing connections

Reducing connections Cracks?

Cracks? Packer range

Packer range Product film

Product film